In the dynamic world of manufacturing, the role of an assembler is pivotal. Assembling various components with precision is not just a job; it’s an art form that keeps the wheels of industries turning. Let’s delve into the specifics of an assembler’s job description, exploring the skills, responsibilities, and the unique aspects that make this career both challenging and rewarding.

Skills and Qualifications

Educational Requirements

To embark on a career as an assembler, a high school diploma or equivalent is typically required. Some roles may demand additional technical education, providing a foundational understanding of assembly processes.

Technical Skills

Assemblers need a keen eye for detail and proficiency in using various tools and equipment. Understanding technical drawings and blueprints is crucial, ensuring accurate assembly according to specifications.

Attention to Detail

Precision is the hallmark of a skilled assembler. From aligning components to checking measurements, attention to detail is a non-negotiable skill in this profession.

Job Responsibilities

Reading Blueprints

Assemblers are often tasked with interpreting intricate blueprints, deciphering the assembly process, and understanding the interplay of components. This step is crucial in ensuring the final product meets quality standards.

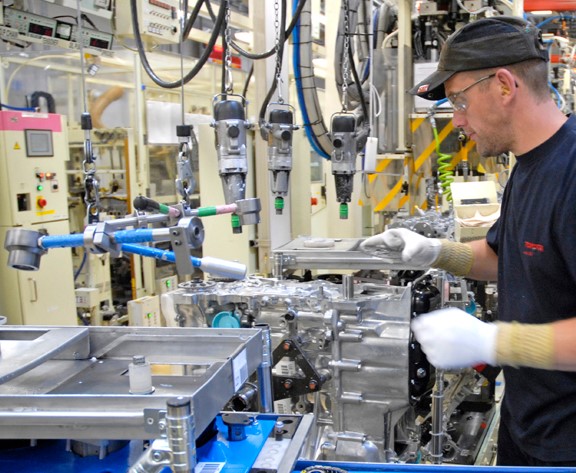

Assembling Components

The core responsibility involves physically assembling components. This hands-on task demands not only technical prowess but also patience and precision.

Quality Control

Assemblers play a vital role in quality control, inspecting finished products to identify defects or deviations from specifications. This ensures that every product leaving the assembly line meets the set standards.

Tools and Equipment

Overview of Common Tools

From screwdrivers to advanced machinery, assemblers use a variety of tools. Familiarity with these tools is essential, and continuous training on new equipment is often part of the job.

Safety Measures

Given the nature of the work, understanding and adhering to safety protocols is paramount. Assemblers work with potentially hazardous tools, requiring a strong commitment to safety practices.

Working Environment

Manufacturing Plants

Assemblers are predominantly found in manufacturing plants, working alongside a team of professionals dedicated to creating a diverse range of products.

Team Collaboration

Collaboration is key in assembly work. Assemblers frequently work in teams, requiring effective communication and coordination to ensure seamless production.

Career Advancement Opportunities

Skill Development

Continuous skill development opens doors for career advancement. Assemblers can undergo training to specialize in specific assembly processes or take on supervisory roles.

Promotional Paths

From entry-level positions, assemblers can climb the career ladder into roles such as team leads, supervisors, and even production managers, bringing leadership and experience to the forefront.

Job Market Trends

Demand for Assemblers

The demand for skilled assemblers remains steady across industries. As technology evolves, new opportunities emerge, creating a sustained need for individuals adept at precision assembly.

Industries Hiring

Assemblers find employment in various sectors, including automotive, electronics, and consumer goods manufacturing. Diversifying skills can open doors to exciting opportunities in different industries.

Challenges in the Role

Monotony

The repetitive nature of assembly work can pose a challenge, requiring assemblers to find ways to stay engaged and maintain focus throughout their shifts.

Physical Demands

The job can be physically demanding, necessitating good health and stamina. Regular breaks and ergonomic considerations help address these challenges.

How to Land an Assembler Job

Crafting a Resume

Highlighting attention to detail, technical skills, and relevant experience is crucial in a resume. Tailoring it to the specific job description increases the chances of standing out.

Acing the Interview

Demonstrating hands-on skills, problem-solving abilities, and a commitment to safety during interviews can leave a lasting impression on potential employers.

Advantages of an Assembler Career

Stability

In a world where job markets fluctuate, assembler positions offer stability. The consistent demand for manufactured goods ensures a continuous need for skilled assemblers.

Entry-Level Opportunities

Assemblers often serve as a stepping stone for individuals entering the manufacturing industry. It provides a platform for gaining valuable experience and exposure to various processes.

Impact of Technology

Automation in Assembly

Advancements in technology, including automation, are changing the landscape of assembly work. Assemblers must adapt and embrace new technologies to stay relevant in the evolving job market.

Adaptation and Training

Ongoing training in technological advancements ensures that assemblers can seamlessly integrate new tools and processes into their workflow.

Industry-specific Assembler Roles

Automotive Assembly

Assemblers in the automotive industry work on constructing vehicles, requiring specialized knowledge of automotive components and assembly techniques.

Electronics Assembly

In electronics assembly, precision is paramount. Assemblers in this sector focus on creating intricate electronic devices, from circuit boards to consumer electronics.

Personal Stories

Success Stories in Assembler Careers

Hearing the journeys of successful assemblers can inspire aspiring individuals, shedding light on the diverse paths to success within the field.

Real-Life Challenges

Sharing real-life challenges faced by assemblers humanizes the profession, offering a glimpse into the resilience required to overcome obstacles in the manufacturing world.

Tips for Success

Time Management

Efficient time management is crucial in assembly work. Assemblers must balance speed with precision to meet production targets without compromising quality.

Continuous Learning

Staying abreast of industry trends and continuously upgrading skills ensures that assemblers remain competitive and adaptable in a dynamic job market.

Conclusion

In conclusion, the role of an assembler is more than just assembling components; it’s about precision, teamwork, and adaptability. Assemblers play a vital role in the manufacturing ecosystem, contributing to the creation of products that shape our daily lives.

Frequently Asked Questions

- Are there specific certifications required for an assembler job?

While not always mandatory, certifications in assembly techniques or safety can enhance your profile. - Is automation a threat to assembler jobs?

Automation brings changes, but assemblers can stay relevant by adapting to new technologies. - What industries offer the most opportunities for assemblers?

Automotive, electronics, and consumer goods manufacturing are prominent sectors hiring skilled assemblers. - Can an assembler career lead to managerial roles?

Yes, with experience and skill development, assemblers can progress into supervisory and managerial positions. - How physically demanding is the assembler job?

The job can be physically demanding, emphasizing the importance of good health and ergonomic practices.